NO-RESIDUE™ laundry bags meet required standards of strength and barrier whilst negating the contamination risk when handling dirty linen

NO-RESIDUE™ laundry bags meet required standards of strength and barrier whilst negating the contamination risk when handling dirty linen

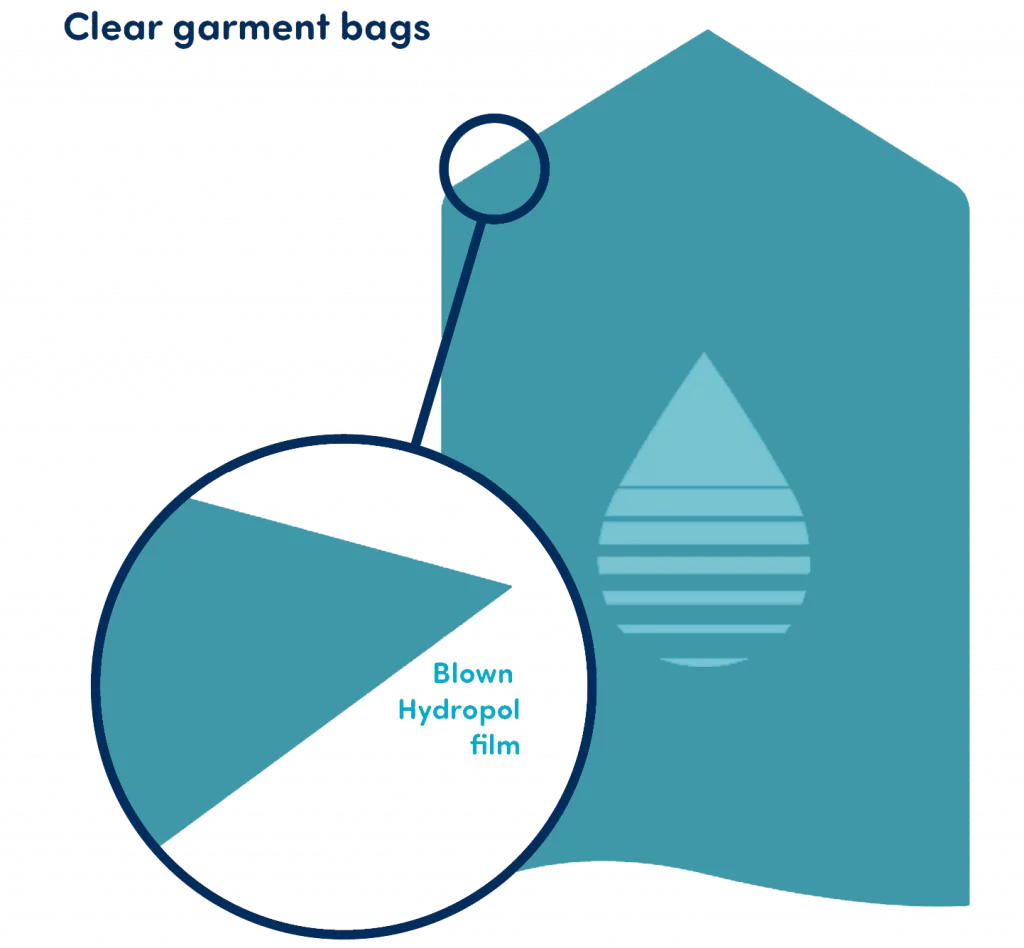

Garment bags made from Hydropol™ are biodegradable, anti-static, non-toxic, marine safe and all raw materials are listed as approved as direct food additives and food contact by EU and US regulatory listings.

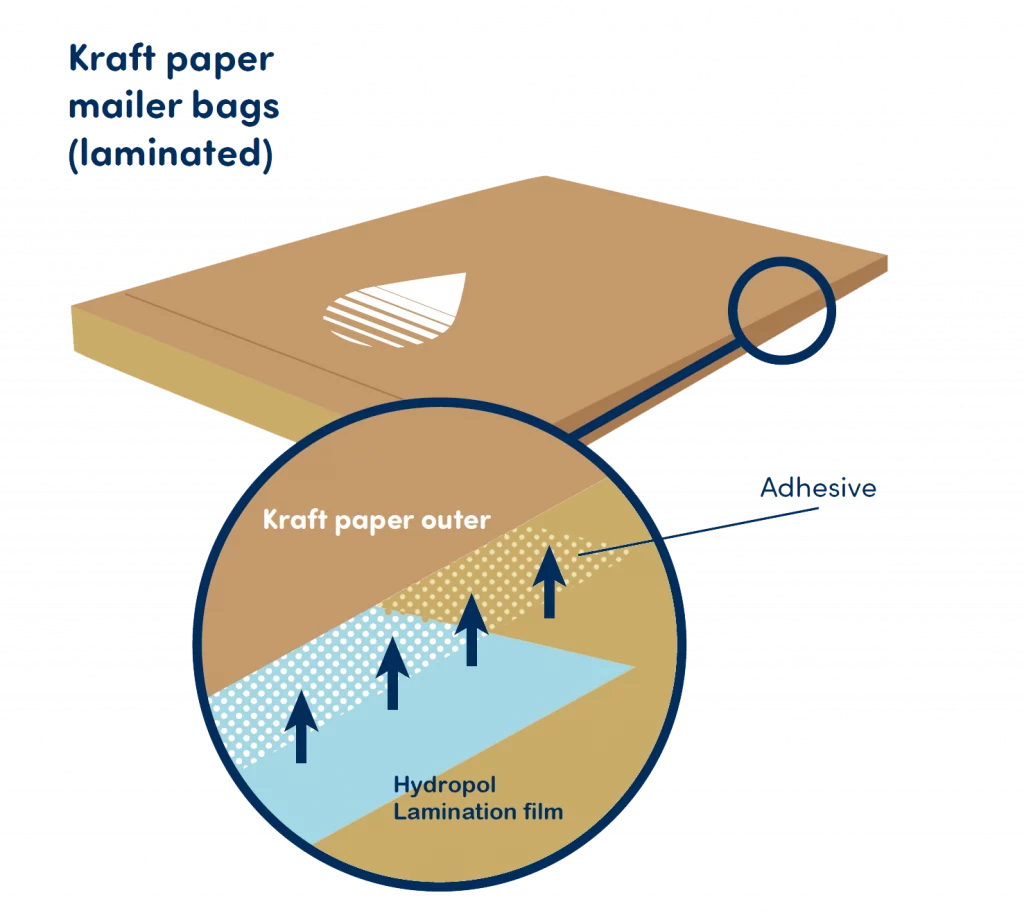

When Hydropol is extrusion coated onto paper or board the resulting material can be recycled in existing paper/board recycling streams and enables 100% of the valuable paper fibre to be recovered – meaning unrecyclable packaging can be fully recycled.

Hydropol™ 33104P + ABX Blown film + Solvent free lamination to paper

Mailing bags

Paper Recycling

Paper recycling enables fibre recovery from the paper component, Hydropol™ dissolves and biodegrades in wastewater treatment plant. Hydropol™ can be used as fuel in an AD process where available. If littered product will biodegrade.

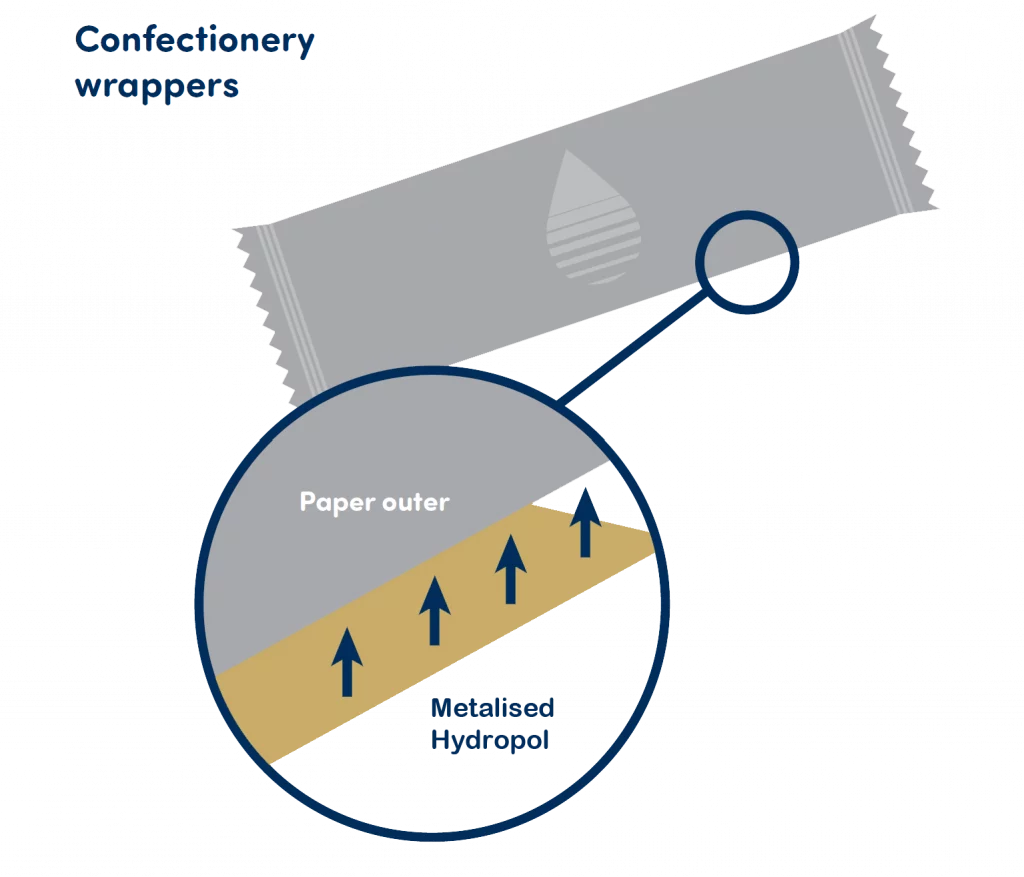

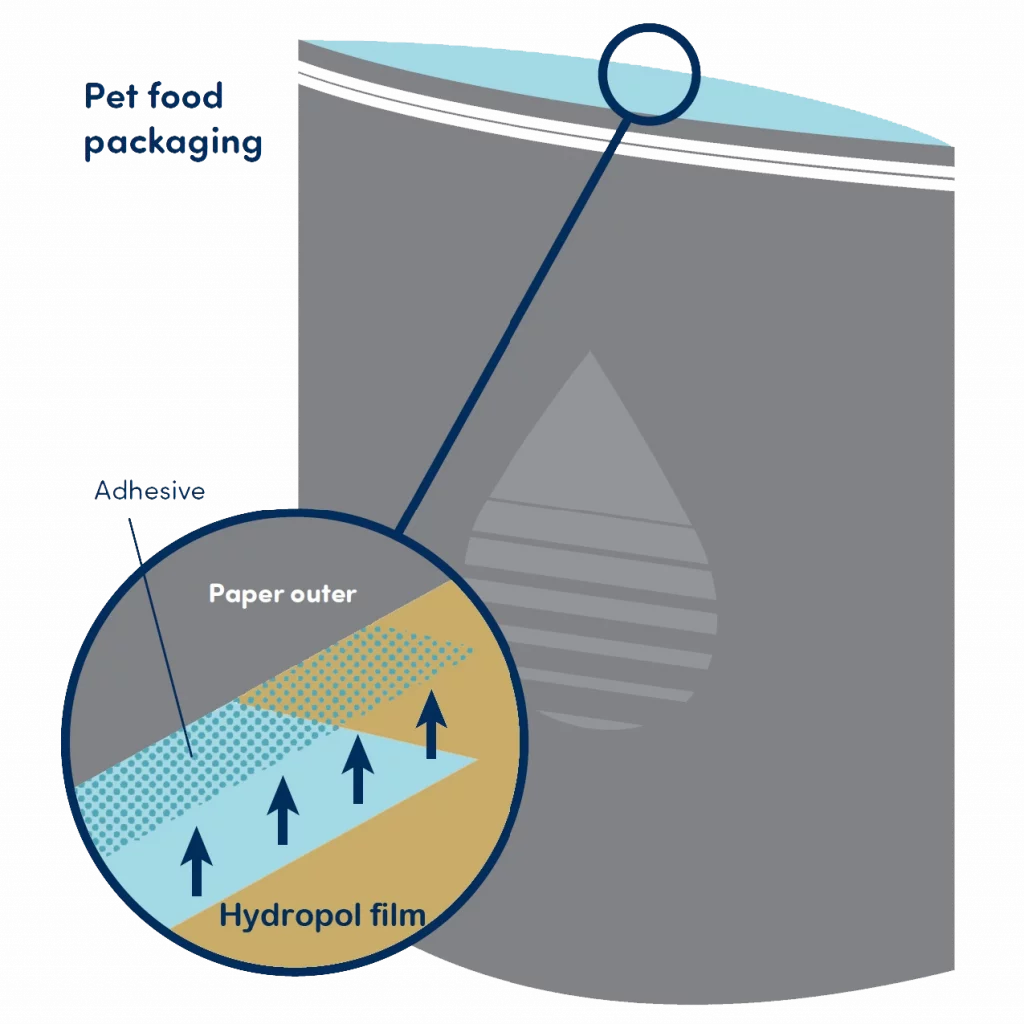

Hydropol™ 33212P extrusion coating onto Kraft paper

Mailing bags, confectionery, Pet food

Paper Recycling

Paper recycling enables fibre recovery from the paper component, Hydropol™ dissolves and biodegrades in wastewater treatment plant. Hydropol™ can be used as fuel in an AD process where available. If littered product will biodegrade.

Hydropol Blown film 3 layer coex construction using Hydropol™ 33104P then solvent free lamination to paper

Dry pet food sacks

Paper Recycling

Paper recycling enables fibre recovery from the paper component, Hydropol dissolves and biodegrades in wastewater treatment plant. Hydropol™ can be used as fuel in an AD process where available. LDPE will be captured and sent to incineration for energy or diverts to landfill.

Hydropol™ 30164P Mono blown film

✓ Garment bags

✓ Garbage bags

✓ Mailing bags

✓ Retail bags

✓ ESD bags

✓ Laundry bags

✓ Food waste bags (AD)

✓ Gloves

✓ Aprons

Dissolve in hot water

Hydropol™ dissolves and biodegrades in wastewater treatment plant. Hydropol™ can be used as fuel in an AD process where available.

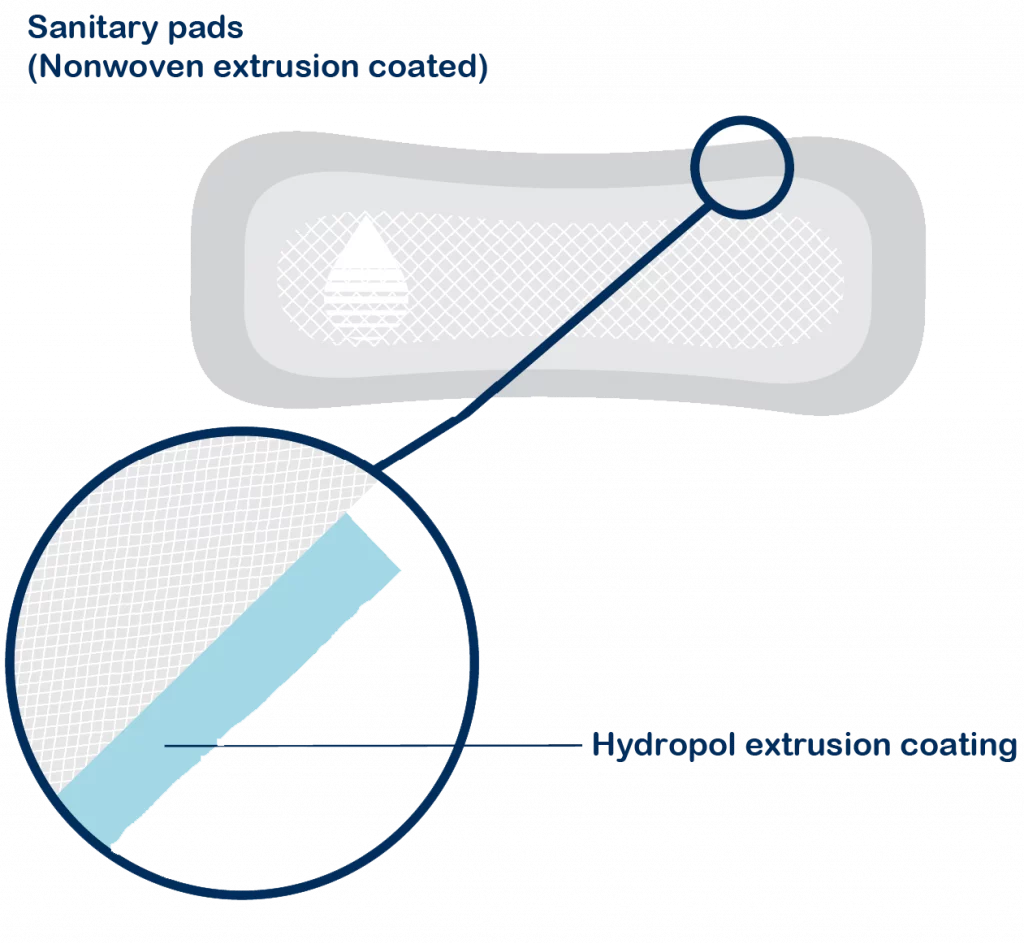

Non-woven extrusion coated with 33212P Hydropol™ for barrier layer

Sanitary Products

Flushable

Water dispersible nonwoven product allows for product to be flushed down standard toilets. Hydropol™ also disperses and breaks down in the water meaning that build ups and blockages in sewer systems can be avoided. Hydropol™ will biodegrade in wastewater treatment facilities.

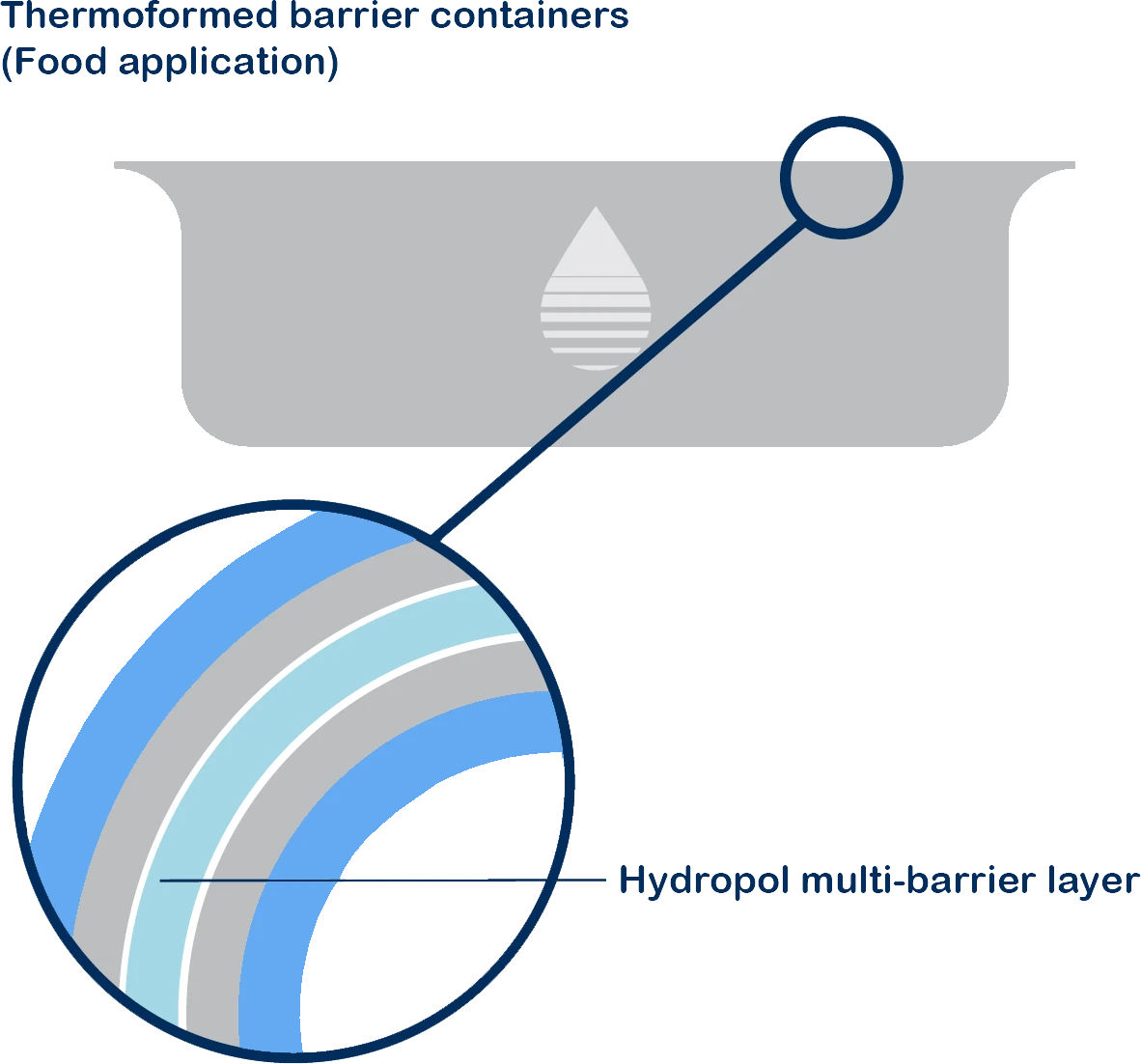

Hydropol™ multi-barrier layer part of thermoformed packaging

Thermoformed barrier trays and cups

Plastics recycling

Hydropol doesn’t interfere with PP/PET recycling processes. Adding Hydropol as a barrier layer makes it easier to remove than conventional materials

Hydropol™ multi-barrier layer part of thermoforme d packaging

Thermoformed barrier trays and cups

Plastics recycling

Hydropol doesn’t interfere with PP/PET recycling processes. Adding Hydropol as a barrier layer makes it easier to remove than conventional materials

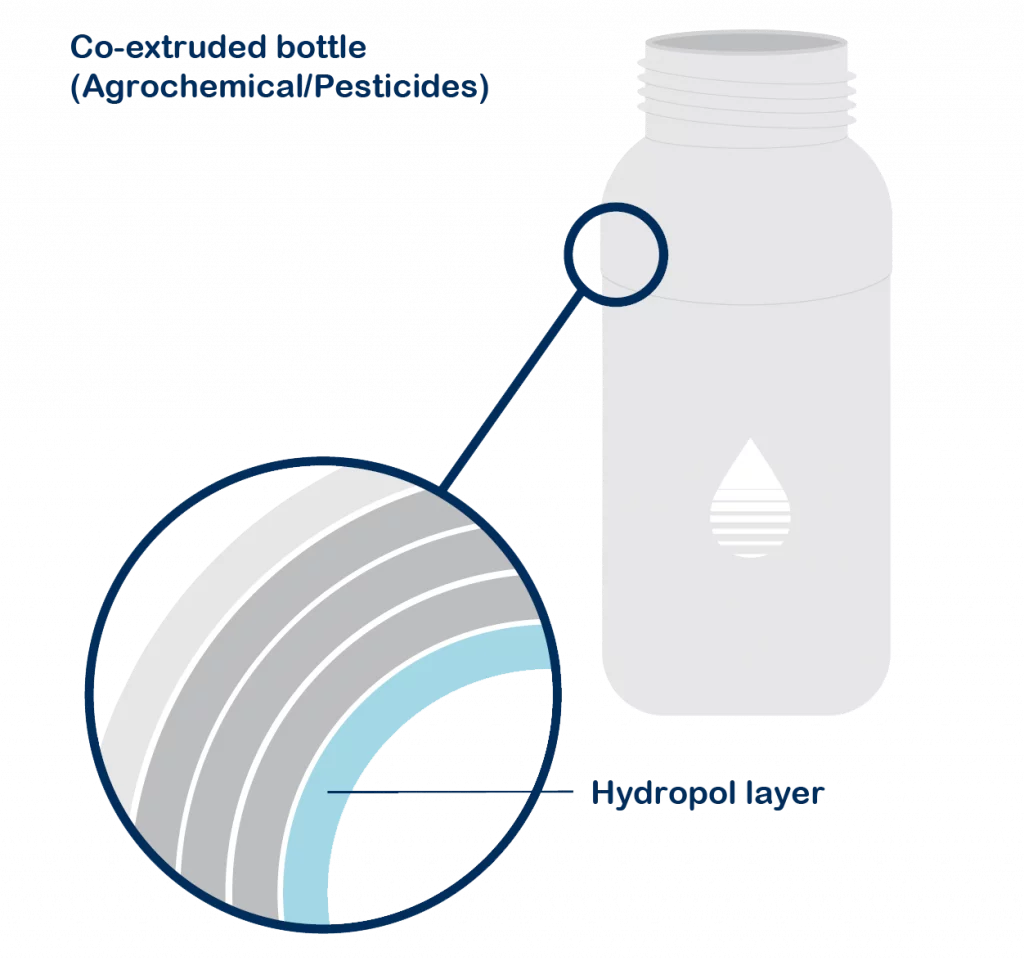

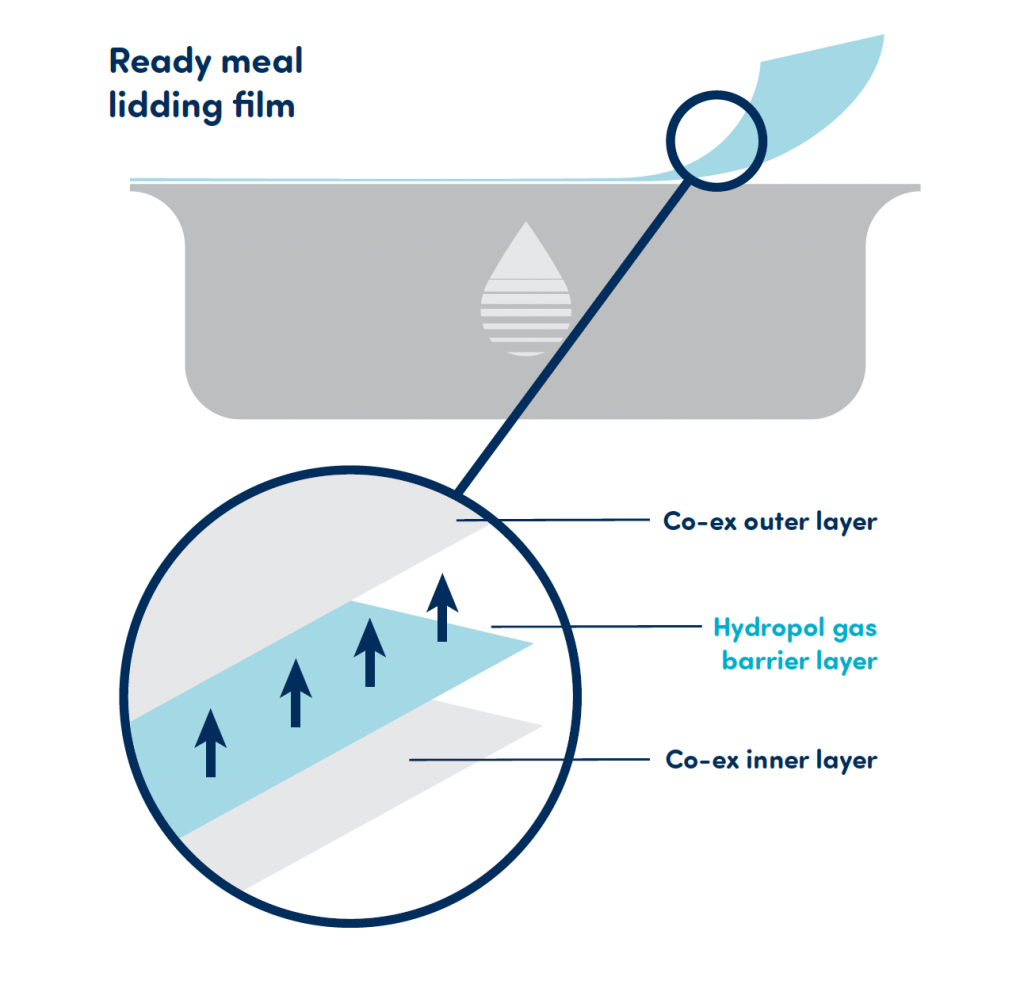

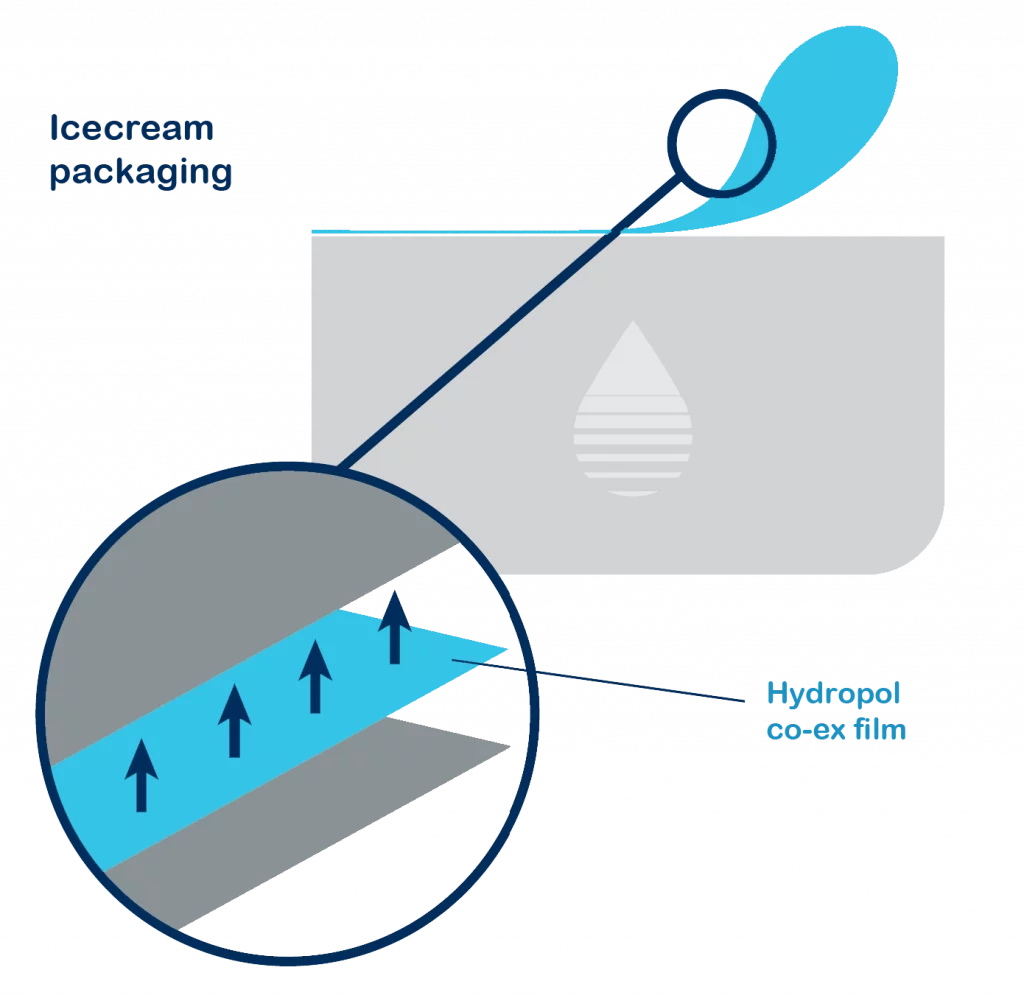

Hydropol™ gas barrier layer as part of co-ex barrier construction

Transparent barrier lid film, bags, pouches, flow packs

Flexible film recycling

Hydropol doesn’t interfere with PP/PET recycling processes. Adding Hydropol as a barrier layer makes it easier to remove than conventional materials

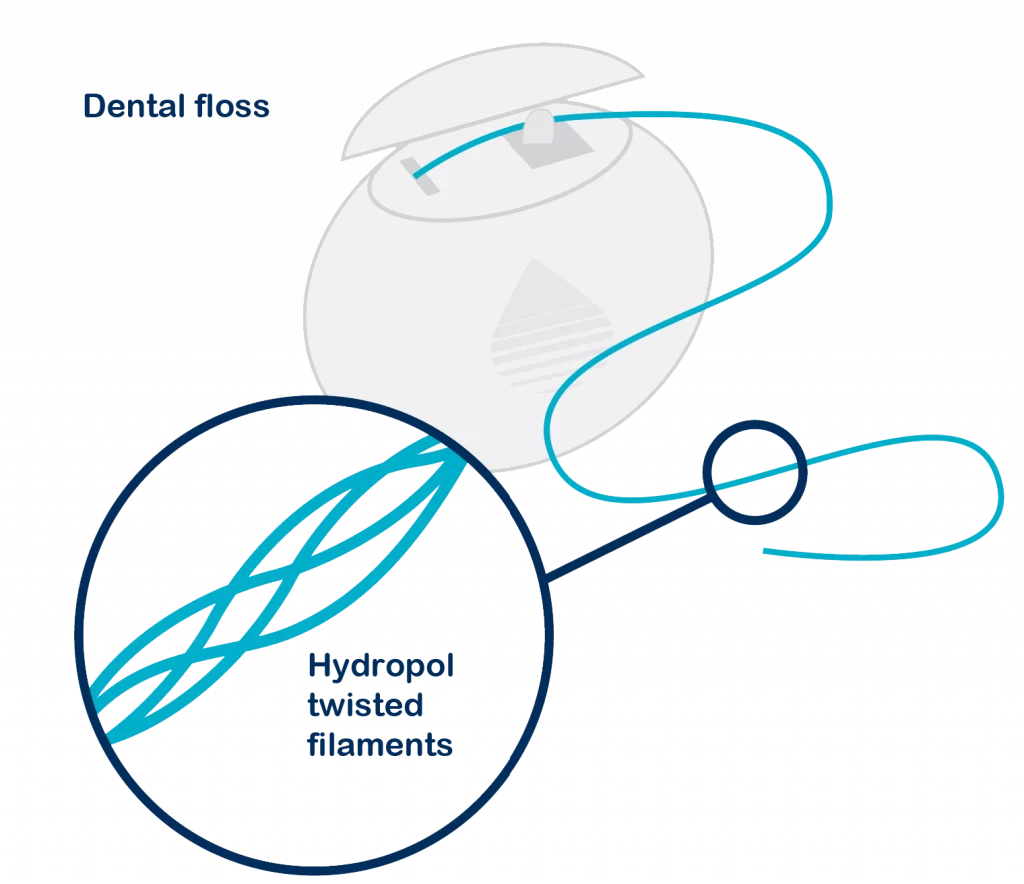

Hydropol™ 33201P multifilament extrusion + filament twisting and wax coating

Dental floss

Dissolve in hot water

Hydropol™ filaments maintain mechanical properties during flossing but then dissolves when rinsed down sink and biodegrade in wastewater treatment plant. If littered product will biodegrade.

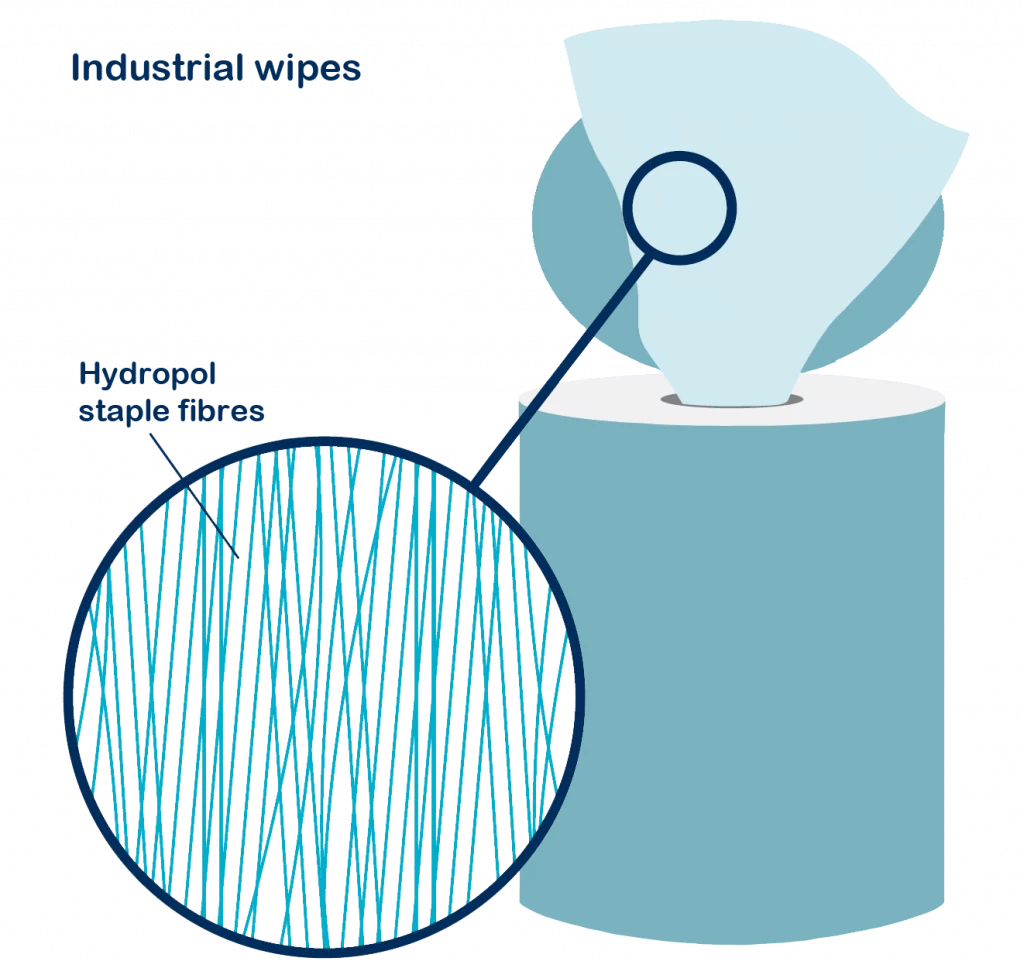

Hydropol™ 33201P multifilament extrusion + airlaid / wetlaid and hydroentangl ement

Wipes, hygiene / personal care, medical Single use nonwovens Fiber blends with cellulosic materials and biomaterials. Replacement polyester and polyolefin fibres

Wastewater – Flushable Biodegradation – Composting – Landfill

Hydropol™ fibers break down in simulated drain line and sewer conditions and biodegrade in wastewater treatment plant. In mixed recycling, Hydropol™ fibers can be washed away using hot water to prevent contamination allowing other materials to be recovered or diverted accordingly.

Hydropol™ 33205P or 33201P Spunbond or meltblown + Thermal bonding, lamination

Single use nonwovens wipes, hygiene/ personal care, cosmetic, medical, filtration, packaging

Wastewater Biodegradation – composting, anaerobic and aerobic conditions

In mixed recycling, Hydropol™ fibers can be washed away using hot water to prevent contamination allowing other materials to be recovered or diverted accordingly. Hydropol™ will completely disintegrate and biodegrade in both aerobic and anaerobic conditions, and in wastewater treatment facilities.

Nonwoven pad made from short cut fibers made from Hydropol™

Sanitary Products

Flushable

Water dispersible nonwoven product allows for product to be flushed down standard toilets. Hydropol™ also disperses and breaks down in the water meaning that build ups and blockages in sewer systems can be avoided. Hydropol™ will biodegrade in wastewater treatment facilities.

Combinations with other biopolymers e.g. co-ex Hydropol™ + Biohybrid layer(s)

Lidding film

Biodegradation – composting, anaerobic and aerobic conditions

When Hydropol is combined with compostable biopolymers the film retains its compostability whilst adding barrier properties.

Hydropol™ 30164P injection molded

COVID test kits Detergent bottles Golf tees Cosmetic wands

Plastics recycling

When made from 100% Hydropol, items can be recycled. When combined with other materials, disposal depends on its construction.

WhatsApp us